An internal combustion engine is an engine that is powered by the expansion of hot combustion products of fuel directly acting within an engine. A piston internal combustion engine works by burning hydrocarbon or hydrogen fuel that presses on a piston; and a jet engine works as the hot combustion products press on the interior parts of the nozzle and combustion chamber, directly accelerating the engine forwards.

By way of contrast, an external combustion engine such as a steam engine, does work when the combustion process heats a separate working fluid, such as water or steam, which then in turn does work.

Jet engines, rockets and gas turbines are classed as internal combustion engines, but the term "internal combustion engine" is often loosely and incorrectly used to refer to piston internal combustion engine in which combustion is intermittent and the products act on reciprocating machinery, the most common subtype of this kind of engine.

Operation

All internal combustion engines depend on the exothermic chemical process of combustion: the reaction of a fuel, typically with air, although other oxidisers such as nitrous oxide may be employed.

The most common fuels in use today are made up of hydrocarbons and are derived from petroleum. These include the fuels known as diesel, gasoline and liquified petroleum gas. Some have theorized that in the future hydrogen might replace such fuels. The advantage of hydrogen is that its combustion produces only water. This is unlike the combustion of hydrocarbons which also produces carbon dioxide and as a result of incomplete combustion: carbon monoxide and nitrous oxides (NOx).

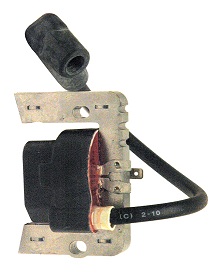

All internal combustion engines must have a means of ignition to promote combustion. Most engines use either an electrical or a compression heating ignition system found in diesel engines. Electrical ignition systems generally rely on a lead-acid battery and an induction coil to provide a high voltage electrical spark to ignite the air-fuel mix in the engine's cylinders. This battery can be recharged during operation using an alternator driven by the engine. Compression heating ignition systems (Diesel engines) rely on the heat created in the air by compression in the engine's cylinders to ignite the fuel when it is injected.

Once successfully ignited and burnt, the combustion products (hot gases) have more available energy than the original compressed fuel/air mixture (which had higher chemical energy). The available energy is manifested as high temperature and pressure which can be translated into work by the engine. In a reciprocating engine, the high pressure product gases inside the cylinders drive the engine's pistons.

Once the available energy has been removed the remaining hot gases are vented (often by opening a valve or exposing the exhaust outlet) and this allows the piston to return to its previous position (Top Dead Center - TDC). The piston can then proceed to the next phase of its cycle (which varies between engines). Any heat not translated into work is a waste product and is removed from the engine either by an air or liquid cooling system.

Engine cycle

Engines based on the two-stroke cycle use two strokes (one up, one down) for every power stroke and are used in lawnmowers, mopeds, outboard motors and some motorcycles. They are generally louder, less efficient, more polluting, and smaller than their four-stroke counterparts. Engines based on the four-stroke cycle or Otto cycle have one power stroke for every four strokes (up-down-up-down) and are used in cars, larger boats and larger aircrafts. They are generally quieter, more efficient and larger than their two-stroke counterparts. There are a number of variations of these cycles, most notably the Atkinson and Miller cycles. Diesel engines use a four-stroke cycle, but with a compression heating ignition system it is possible to talk separately about a diesel cycle. The Wankel engine operates with the same separation of phases as the four-stroke engine, but would more properly be called a four-phase engine, since there are no reciprocating strokes and the phases occur in separate locations in the engine.

Fuel type

Diesel engines are generally heavier, noisier and more powerful at lower speeds than gasoline engines. They are also more fuel-efficient in some circumstances and are used in heavy road-vehicles, ships and some locomotives. Gasoline engines are used in most other road-vehicles including most cars, motorcycles and mopeds. Both gasoline and diesel engines produce significant emissions. There are also engines that run on hydrogen, methanol, ethanol, liquefied petroleum gas (LPG) and biodiesel.

Engine configuration

Internal combustion engines can be classified by their configuration which affects their physical size and smoothness (with smoother engines producing less vibrations). Common configurations include the straight or inline configuration, the more compact V configuration and the wider but smoother flat or boxer configuration. Aircraft engines can also adopt a radial configuration which allows more effective cooling. More unusual configurations, such as "H", "X", or "W" have also been used.

Multiple-crankshaft configurations do not necessarily need a cylinder head at all, but can instead have a piston at each end of the cylinder, called an opposed piston design. This design was used in the Junkers Jumo 205 diesel aircraft engine, using two crankshafts, one at either end of a single bank of cylinders, and most remarkably in the Napier Deltic diesel engines, which used three crankshafts to serve three banks of double-ended cylinders arranged in an equilateral triangle with the crankshafts at the corners. It was also used in single-bank locomotive engines, and continues to be used for marine engines, both for propulsion and for auxiliary generators. The Gnome Rotary engine, used in several early aircraft, had a stationary crankshaft and a bank of radially arranged cylinders rotating around it. Technically this is a "rotating" engine, to distinguish it from Wankel "rotary" engines.

Engine capacity

An engine's capacity is the displacement or swept volume by the pistons of the engine. It is generally measured in litres or cubic inches for larger engines and cubic centimetres (abbreviated to cc's) for smaller engines. Engines with greater capacities are usually more powerful and provide greater torque at lower rpms but also consume more fuel.

Apart from designing an engine with more cylinders, there are two ways to increase an engine's capacity. The first is to lengthen the stroke and the second is to increase the piston's diameter. In either case, it may be necessary to make further adjustments to the fuel intake of the engine to ensure optimal performance.

An engine's quoted capacity can be more a matter of marketing than of engineering. The Morris Minor 1000, the Morris 1100, and the Austin-Healey Sprite Mark II all had engines of the same stroke and bore according to their specifications, and were from the same maker. However the engine capacities were quoted as 1000cc, 1100cc and 1098cc respectively in the sales literature and on the vehicle badges.

History

The earliest and simplest internal combustion engines seem to have been rockets in the form of fireworks, developed by the Chinese as early as 300 BCE, using gunpowder. They were essentially toys until the 11th century when they evolved into use for weaponry.

Francois Issac de Rivaz built the first reciprocating internal combustion engine in 1807. However his engine was impractical for many uses because it lacked power and relied upon a mixture of hydrogen and oxygen for fuel.

The first patent for an internal combustion engine was awarded by the U.S. Patent Office in 1826 to Samuel Morey. This was one of the X-Patents lost in a fire in July 1836 and not recovered until 2004.

In 1858, Jean Lenoir invented the first practical internal combustion engine. It relied upon coal gas that was sucked into the cylinder at the beginning of each stroke and then ignited to push the piston to the other end of the cylinder. This process was then repeated at the other end of the cylinder making the engine double-acting.

In 1867 Nikolaus Otto built the first four-stroke internal combustion engine. This engine proved more efficient than Lenoir's design and was successfully marketed for industrial purposes. The design was later improved by Gottlieb Daimler who focused on making the technology practical for use in automobiles most notably by incorporating a gasoline carburettor. In 1890 Wilhelm Maybach built the first four-cylinder internal-combustion engine. Both Maybach and Daimler were originally employees of Otto's company but had left in 1882 to form their own company.

Over the same time period the two-stroke internal combustion engine was being perfected, which had been invented in 1867 by Sir Dougald Clerk. The design was later simplified by Joseph Day in 1891.

In 1930 Sir Frank Whittle patented the use of a gas turbine for jet propulsion. The first successful use of this engine was in April, 1937. Ernst Heinkel Aircraft flew the first flight in 1939 of a gas turbine jet, the HE178.

In 1956, Felix Wankel developed and ran the first practical rotary combustion engine.

Applications

Internal combustion engines are most commonly used for equipment and mobile propulsion systems. They appear in mowers, chainsaws, cars, motorbikes, many boats, and in a wide variety of aircraft, locomotives and many other applications. In jet aircraft and large ships, they appear mostly in the form of gas turbines. They are also be used for electric generators and by industry.

For many non-mobile applications, an electric motor is a competitive alternative. In the future electric motors may also become competitive for most mobile applications. However, at the moment the high cost and weight of batteries and the lack of affordable onboard electric generators such as fuel cells restrict their use.

Parts

The parts of an engine vary depending on the engine's type. For a four-stroke engine, key parts of the engine include the crankshaft, one or more camshafts and valves. For a two-stroke engine, there may simply be an exhaust outlet and fuel inlet instead of a valve system.

In both types of engines, there are one or more cylinders and for each cylinder there is a spark plug, a piston and a crank. A single sweep of the cylinder by the piston in an upward or downward motion is known as a stroke and the downward stroke that occurs directly after the air-fuel mix in the cylinder is ignited is known as a power stroke.

A Wankel rotary engine has a triangular rotor that orbits in an epitroichoidal (figure 8 shape) chamber around an eccentric shaft. The four phases of operation (intake, compression, power, exhaust) take place in separate locations, instead of one single location as in a reciprocating engine.

Additional information and source: Internal combustion engine